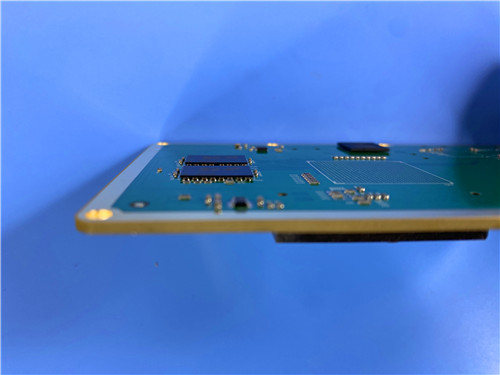

The Power of 370HR Exploring High-Reliability PCBs for Critical Applications

1.Introduction to 370HR

Isola's 370HR is a high-performance 180°C glass transition temperature (Tg) FR-4 system for multilayer Printed Circuit Board (PCB) applications. It's manufactured with a unique high-performance multifunctional epoxy resin, reinforced with electrical grade (E-glass) glass fabric. The system is also laser fluorescing and UV blocking for maximum compatibility with Automated Optical Inspection (AOI) systems, optical positioning systems, and photoimageable solder mask imaging. 370HR has proven to be best in class for sequential lamination designs.

2.Key Features of 370HR PCBs

High Thermal Performance

Tg: 180°C (DSC)

Td: 340°C (TGA @ 5% wt loss)

Low X/Y-Axis CTE of 13/14ppm/°C for reliability

T260: 60 minutes

T288: 30 minutes

RoHS Compliant

UV Blocking and AOI Fluorescence

High throughput and accuracy during PCB fabrication and assembly

CAF Resistant

Superior Processing: Closest to conventional FR-4 processing

3.PCB Construction Details:

| Specification | Details |

|---|---|

| Base Material | 370HR |

| Layer Count | 6-layer |

| Board Dimensions | 102.87mm x 128.5 mm (4up), +/- 0.15mm |

| Minimum Trace/Space | 4/4 mils |

| Minimum Hole Size | 8 mils |

| Vias | 198 |

| Blind/Buried Vias, Slot Holes | No Blind or Buried Vias, No Slotted Holes |

| Finished Copper Weight | 1 oz signal and plane layers |

| Top/Bottom Silkscreen | White |

| Top/Bottom Solder Mask | Green |

| Board Thickness | 40.4 mils / 1.02mm +/- 0.05mm |

| Edge Routing | All Edges Tab-Routed, Non-Plated Holes for Breakouts |

| UL Mark | UL Mark on PCB Required |

| Electrical Test | Electrical Test Required |

| Silkscreen on Pads | Ensure No Silkscreen on Solder Pads |

| Panel Breakouts | Panel Breakouts Required |

| Surface Finish | ENIG, with 0.1um (0.004 mils) gold, for -40°C to +85°C |

4.Impedance Matching

Layer 1: 10mil single end, 50 ohm, reference layer 2

Layer 3: 6mil single end, 50 ohm, reference layer 2

Layer 4: 6mil single end, 50 ohm, reference layer 5

Layer 6: 10mil single end, 50 ohm, reference layer 5

Impedance matching tolerance: +/- 10%

5.PCB Stackup (6-Layer Rigid PCB)

Top Silk Layer

Top Mask Layer

Top Layer (PCB Layer 1) - 1.4mil (1oz)

IS370 HR - 6mil

Ground Plane (PCB Layer 2) - 1.4mil (1oz)

IS370 HR - 6mil

Mid Layer 1 (PCB Layer 3) - 1.4mil (1oz)

IS370 HR - 8mil

Mid Layer 2 (PCB Layer 4) - 1.4mil (1oz)

IS370HR - 6mil

Power Plane (PCB Layer 5) - 1.4mil (1oz)

IS370HR - 6mil

Bot Layer (PCB Layer 6) - 1.4mil (1oz)

Bot Mask Layer

Bot Silk Layer

6.PCB Statistics

Components: 120

Total Pads: 267

Thru Hole Pads: 37

Top SMT Pads: 218

Bottom SMT Pads: 12

Nets: 58

7.Accepted Standards

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2 compliant

Availability: Worldwide production and shipping

8.Target Applications

Computing, Storage & Peripherals

Networking & Communications

Automotive & Transportation

Consumer Electronics

Aerospace & Defense

Medical, Industrial & Instrumentation